Press Releases

Exhibitor news

-

Leading baby product manufacturer and distributor, Obaby, has seen a 30 per cent year-on-year increase in orders and has attributed OrderWise’s ERP and WMS software as a key reason for this growth.

-

IXON is proud to report that it’s found to conform to three ISO standards after an extensive audit: ISO 27001, ISO 27017 and ISO 27701.

-

A new range of indexing levers designed to clamp in restricted spaces without marking the workpiece or equipment is now available.

-

The new Component Software Development Kit makes it easy and secure to quickly develop your own components to completely meet your needs.

-

The Patent recognizes their continued development efforts towards bringing a process patent that involves ultra-low-power wireless sensors and cloud-based software that detects even small changes in t ...

-

During October’s Engineering Design Show, Nicole Piesse Turner of Chatty Hatter recorded some roving live chats with leading industry people as part of That Engineering Chat podcast series.

-

The new Component Software Development Kit makes it easy and secure to quickly develop your own components to completely meet your needs.

-

Ignoring your difficult processes, disjointed systems and disgruntled workforce might seem like the easiest option after the economic downfall, but 2021 proved that

-

DCO Systems solve equipment maintenance, inspection and performance challenges with energy harvesting equipment sensors that are self-powered, maintenance-free and always on. With projects taking plac ...

-

After previously reviewing the combined impact of COVID and Brexit upon the manufacturing and engineering sectors, most recently in May, MHA returned to a short series of questions to track progress. ...

-

During October’s Engineering Design Show, Nicole Piesse Turner of Chatty Hatter recorded some roving live chats with leading industry people as part of That Engineering Chat podcast series.

-

New investment is available to support skills development, talent and training needs in the power electronics, machines and drives (PEMD) industry.

-

New investment is available to support skills development, talent and training needs in the power electronics, machines and drives (PEMD) industry.

-

To enable system operators to move even more freely along the production line, SIGMATEK has developed the “Wireless Roaming Feature” for wireless HMIs. The TüV-certified, wireless operating solution w ...

-

The newly developed battery powered hydraulic crimping tool, EKWF120 ML will simplify your work and simultaneously ensure optimum crimping quality. Using a square-cam mechanism, the EKWF120ML crimps b ...

2024 content agenda

Free-to-attend presentations are delivered by manufacturing and engineering experts covering Design & Innovation, Maintenance, IIoT & Connectivity, Digital Transformation, Data & AI, Fluid Power & Air-Tech. Through a series of case studies, interviews and panels, discover the industry latest first-hand.

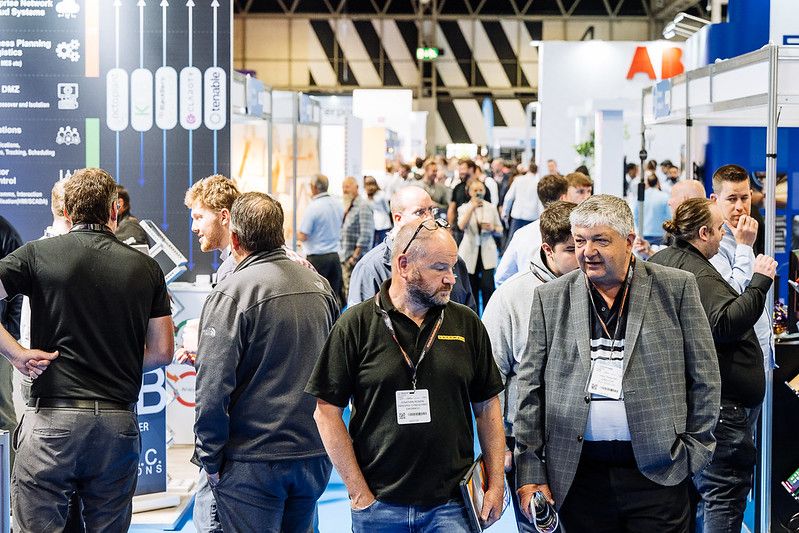

Connect+ Live

Our specialist Hosted Buyer Programme partners will be on hand to connect visitors with the exhibitors they want to meet, to ensure the most efficient use of their time.

Guitar Competition

Ready to showcase your guitar talents to the world? Play a classic intro to a song in our recording booth and be in with a chance to win a bespoke 3D printed guitar!

Enginuity Skills Awards 2024

We are delighted to announce that the 10th annual Enginuity Skills Awards will be taking place as part of Smart Manufacturing & Engineering Week!

Best of British Showcase

Join us in a celebration of domestic manufacturing, featuring world-beating new designs, innovative modes of manufacture, products that redefine categories, and export successes that plant the flag in overseas markets.

FANUC WorldSkills Qualifiers

Taking place at the show is an amazing opportunity for young people to compete and find their passion in the world of robotics.

WorldSkills UK is an independent charity and a partnership between employers, education, and governments. Together, they are raising standards in apprenticeships and technical education to enable more young people get the best start in work and life.

They are working with FANUC to host qualifiers for this year's Industrial Robotics competition at Smart Manufacturing & Engineering Week!

ThrustWSH Project to be showcased at Smart Manufacturing & Engineering Week!

The ThrustWSH project is the follow on from the team’s previous World Record projects – the 1983 Thrust2 World Land Speed record 633mph, the 1997 ThrustSSC first ever supersonic land speed record 763mph and the 1000MPH BloodhoundSSC project which was lost due to non payment of a formal grant offer. They will be doing an exclusive showcase at the show!

)

)

)

)

)

)

)

)

)

)

)

SIGMATEK.jpg/fit-in/500x500/filters:no_upscale())

)