Shock absorber range keeps material handling OEM airborne

ULD’s are unsung yet vital items in the transportation of luggage and freight, typically used in aviation. Rather than loading items in bulk, or loading individual items by hand, cargo or passenger baggage can be loaded onto a ULD container, which is then loaded on and off an aeroplane. The ULD not only means faster cargo and baggage handling, but their use also enables accurate planning of loads and weight distribution.

ULD containers, constructed from aluminium to create a robust yet lightweight frame, typically feature ball transfer units set into the floor to ease the loading and unloading of cargo and baggage. When loaded onto an aircraft, the ULD’s are secured to safely maintain position during flight. A UK materials handling equipment manufacturer wanted to improve the safety of its ULD design, for both operatives as well as the environments they’re used in. The objective was to soften the impact of the side barriers that are deployed when loading and unloading.

Each side of the ULD features a barrier that is lowered to maintain stability on the bed during side loading. After loading, the barriers are returned to their raised position. The barriers are manually operated and are lowered by releasing a latch via a foot-operated pedal. During operation, the barriers can suddenly drop, potentially causing injury to the operator. The force could also damage the loading environment’s bed as well as the ULD itself.

The OEM turned to WDS to specify a shock absorber design that could decelerate and reduce the impact of the barrier. The solution had to be able to provide variable shock absorption and, as the OEM had a requirement for high volume production, the design had to be cost effective. WDS was able to provide the optimum engineering outcome by specifying a self-compensating shock absorber.

Selecting the right shock absorber for the application in order to provide sufficient deceleration, WDS had to consider the barrier’s velocity, mass, propelling force and frequency of cycles. The speed of the descending barrier could vary, depending on its starting position. This meant that adjustable shock absorbers that are set where the factors of impact remain constant would not be suitable. Instead, WDS developed a solution involving a self-compensating shock absorber which greatly improved performance.

The advantage of the self-compensating shock absorber design meant that in the event of a sudden drop or differing forces, the device would still be able to manage the impact and provide sufficient deceleration. While self-compensating shock absorbers are initially selected for high, medium or low speed applications, they function within a range of effective mass, and no other adjustment is required, whether for variations in velocity or propelling force. For the case of the unpredictable loads that can occur on a ULD, WDS’ self-compensating shock absorber was the most flexible option.

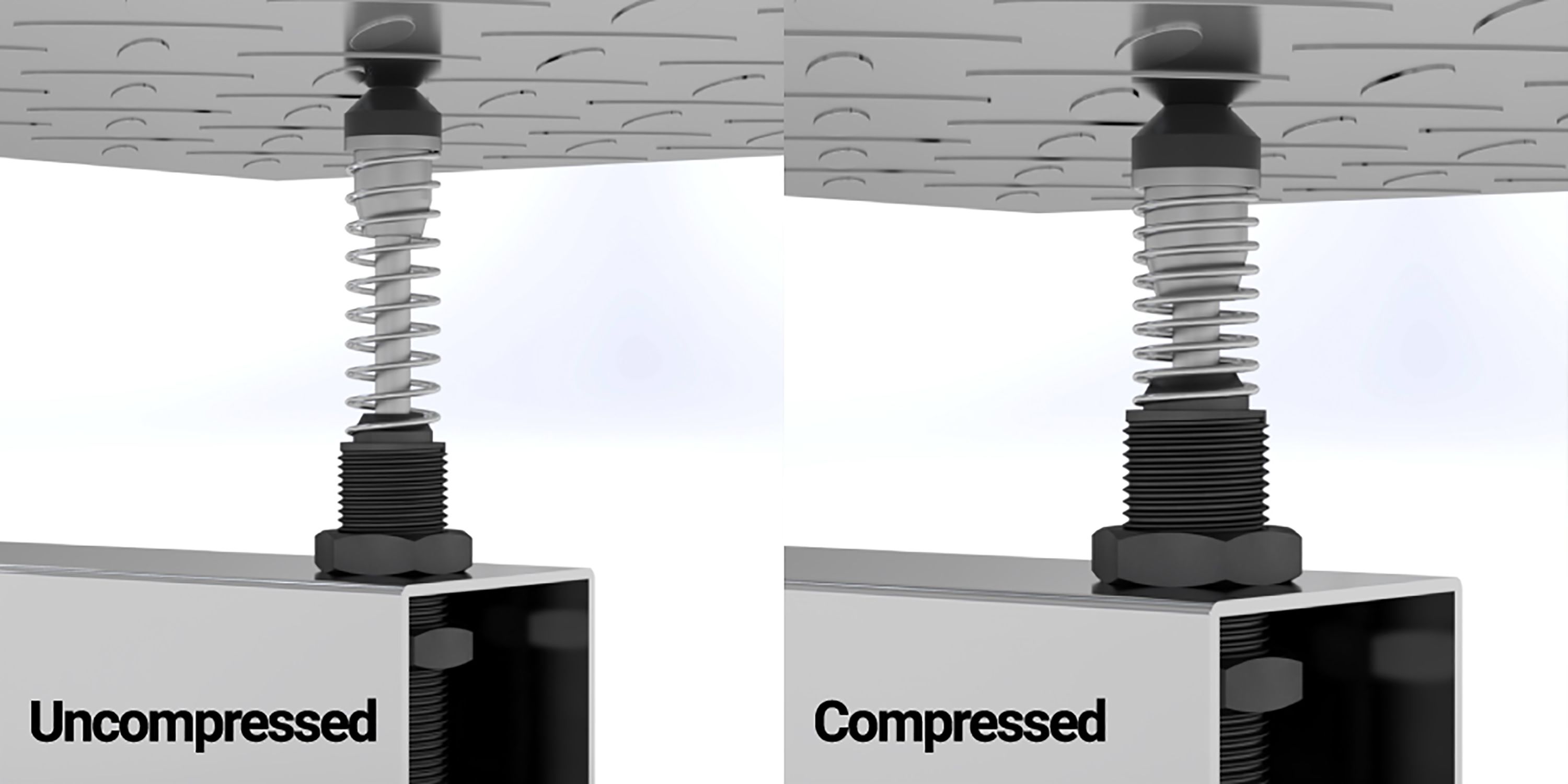

To specify the device, the customer’s average load cycle was assessed, and the appropriate shock absorber was selected by the WDS technical team according to the application’s speed. For installation, the shock absorbers were screwed directly onto the barrier. During the barrier’s descent, they immediately catch the load and support lowering, decelerating the barrier to a safe speed and force. Irrespective of load or speed, the self-compensating shock absorber manages the impact. Rubber caps also remove the potential of damage or marking to the loading/unloading environment.

Constructed from steel, the WDS range of self-compensating shock absorbers provide robust, long-term use and can variously handle a maximum effective mass of up to 1,200kg, a maximum energy per cycle of 98Nm, and a velocity of up to 4m/s.

The material handling OEM is also trialling the shock absorbers across other applications. To calculate whether an adjustable or a self-compensating model is needed, as well as specifying the application’s attributes, WDS’ engineers will advise. With wide stocking and supply directly from its Leeds facility, WDS is also well positioned to rapidly supply OEMs with high volume requirements.

)

)

)